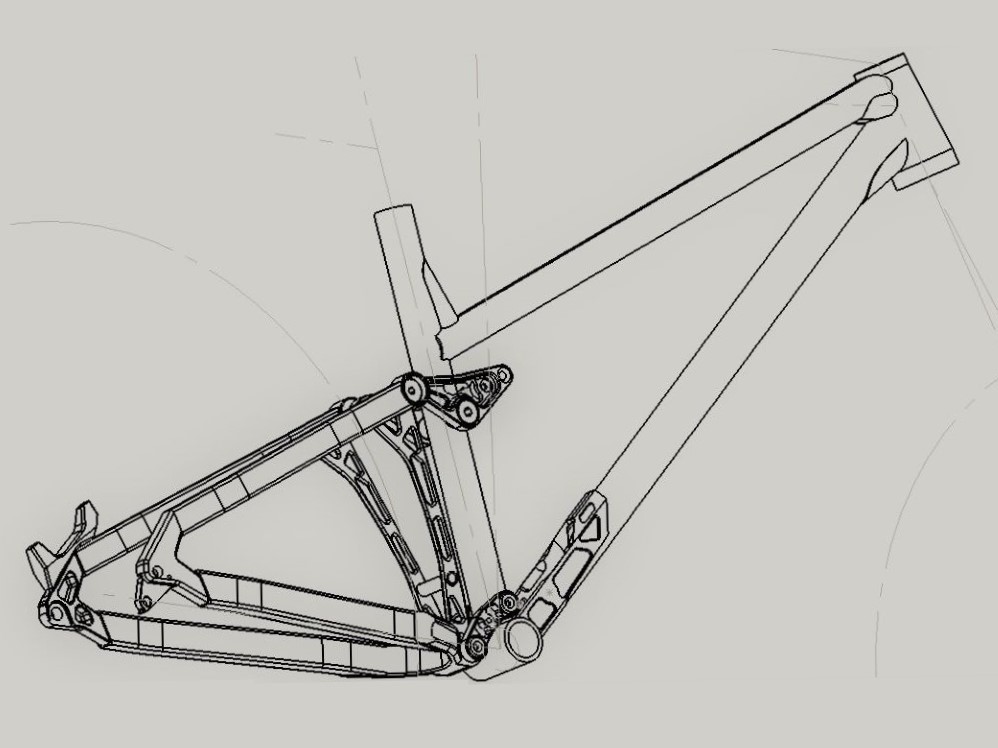

Designing and preparation of technical documentation

At the request of our clients, we prepare projects ranging from simple elements to advanced and complicated constructions. We prepare professional technical documentation for each project, design dedicated welding tools and those used in series production. We employ experienced engineers and design experts who use professional software. We take care about details, so all the products we create are made with specific dimensional tolerances.

TIG welding

We use professional TIG welders to weld aluminium. Depending on the type of alloy, the final product is head-treated or left to temper. After this, product is checked again to avoid deviations.

CNC elements

In our factory we use CNC milling machines and lathes. The details are characterized by precision and assumed tolerancy, which could be use to join to the other components and welded.

In addition, we accept orders for turned or milled components. Production takes place under constant control of technologists.

Other methods of machining metals and other materials

Our offer also includes finishing of supplied elements such as milling, drilling or welding. Based on our wide experiende, we also deal with 3D printing of metals and plastics.

Depending on the order, it is possible to use various types of steel alloys.

Complex implementation and optimization of production

First step of production is creating prototype, which is thoroughly tested, then the first small batch is made. In the next step we adjust the production line so as to maximize the efficiency of work. We are systematically increasing our production capacity thanks to constant development and expansion of our machine park.

For bike assembly we use OEM parts from manufacturers who supply parts for so-called first assembly. On this area we work with brands such as Continental, Shimano, Race Face, Fox, Pinion.